FIELD-READY LUBRICATION & SERVICE SYSTEMS

FASTER. SAFER. EASIER. BUILT FOR REAL WORK

Purpose-built lubrication and on-site servicing systems engineered for agriculture, civil construction, hire fleets, mining support, and remote service operations.

BUILT FOR REAL WORLD SERVICING

Bruder Lube is the specialist lubrication and field service equipment division of Brüder Australia. We design, manufacture, and supply robust systems that simplify fluid handling, reduce downtime, and improve accountability across heavy asset fleets.

Designed for the field

Every system is engineered for harsh, remote, and high-use environments. From harvest support to civil construction sites, Bruder Lube equipment is built to perform where reliability matters most.

Smart, modular engineering

Unlike conventional field units that require decanting and complex setup, Bruder Lube systems use modular, drum-direct designs that streamline oil and fluid transfers while reducing mess and risk.

Manufactured with precision

With in-house CAD design, fabrication, welding, and assembly using Australian aluminium and quality imported Italian oil transfer components, each build reflects Brüder’s commitment to durability and performance.

THE PATENTED LUBE CUBE

Compact. Compressed air powered. Built around industry-standard 205 L drums. The LUBE CUBE eliminates unnecessary handling and simplifies oil changes and fluid transfers in both field and workshop environments.

How it works

Strap a standard 205 L drum to the unit, install the pneumatic pump, connect compressed air, and begin servicing. Swap drums in minutes with minimal spillage and no internal tank filling.

Precision delivery

Digital metered nozzles provide accurate fluid tracking for accountability, maintenance planning, and job costing clarity.

Integrated waste recovery

Waste oil is recovered using a diaphragm pump with reversible valve and hose reel, supporting cleaner job sites and responsible servicing practices.

POWER FULL PERFORMANCE IN THE FIELD

Designed to reduce downtime, improve safety, and deliver confident servicing outcomes wherever your fleet operates.

Reduce turnaround time with drum-direct pumping and rapid oil changeover.

Minimise spills, cross-contamination, and post-service cleanup.

Digital metering improves accountability and servicing visibility.

No electrical requirements; integrates with existing air systems.

Tailored dimensions and layouts to suit your vehicle, trailer, or workshop space.

No electrical requirements; integrates with existing air systems.

CUSTOM SERVICE SOLUTIONS

Bruder Lube delivers more than standalone units. We design complete lubrication and servicing systems aligned to your operational workflow.

Service trucks and trailers

Integrated builds incorporating lubrication systems, pneumatic tools, spill containment, washdown capability, and storage — engineered around your fleet requirements.

Vehicle mounted service pods

Compact pods designed for hydraulic oil, engine oil, transmission fluid, and grease distribution — purpose-built to bolt or weld onto service vehicles.

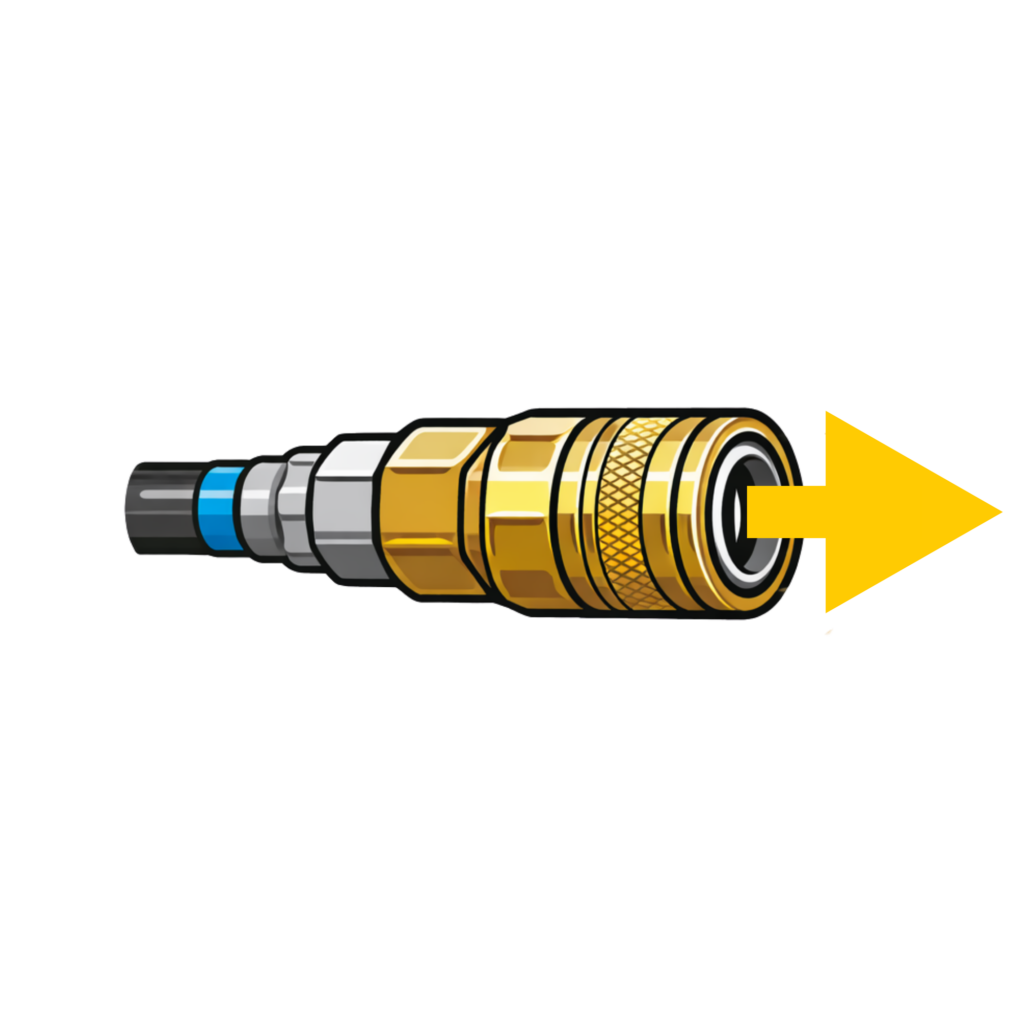

Accessories and transfer equipment

Hose reels, pneumatic piston pumps (3:1 or 5:1 ratios), diaphragm pumps, quick-connect systems, and fluid handling accessories aligned to your configuration.

READY TO SPEC YOUR BRUDER LUBE SYSTEM?

Talk to our team about a tailored configuration that fits your servicing environment, vehicle platform, and operational demands.